Manufacturing Facilities

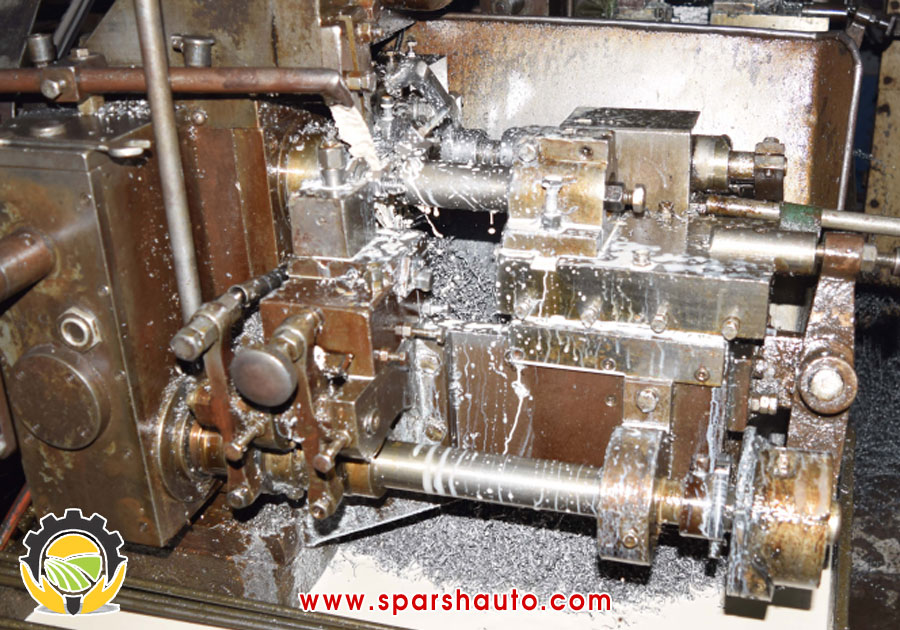

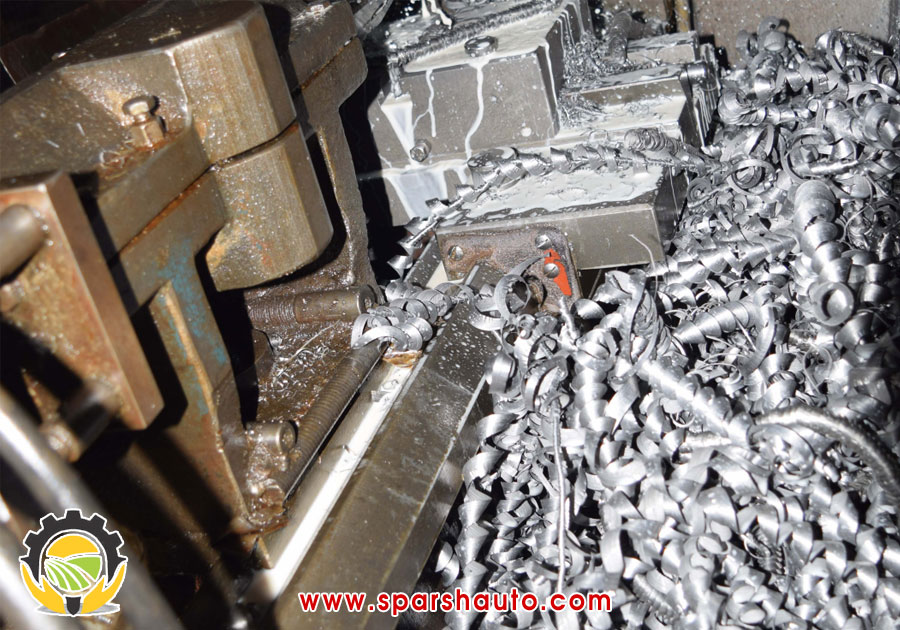

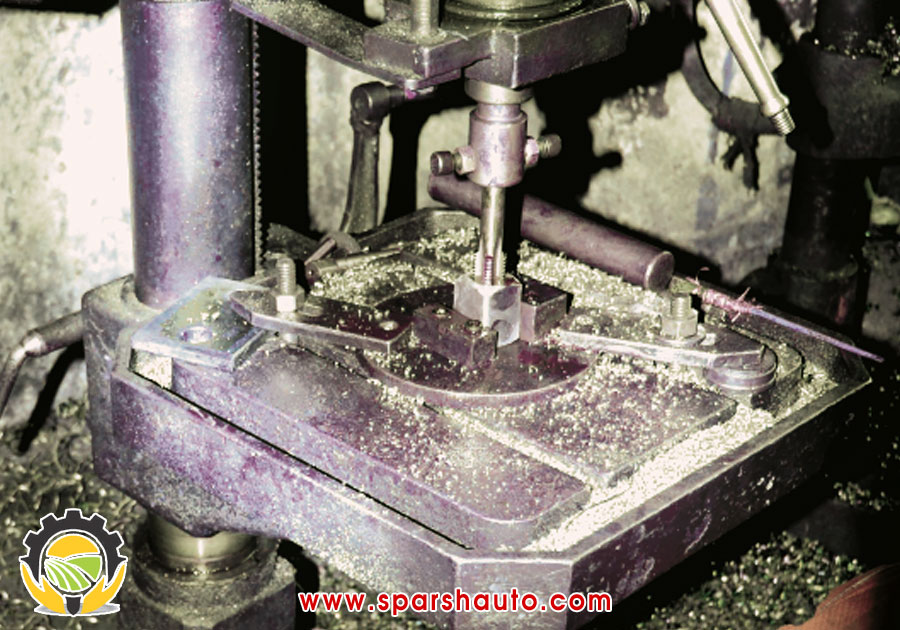

Sparsh Auto possess a state-of-the-art manufacturing unit spread across 2000 Yards. This unit is equipped with advanced and modern machines that help us in catering to the various requirements of our clients within a stipulated time frame. Our machines are highly upgraded and handled by a team of experienced engineers. They use optimum quality raw materials for manufacturing our range.

| Machinery | Nos. |

|---|---|

| AUTOMATES | 25 |

| SPM MILLINGS | 2 |

| POWER PRESS | 4 |

| HYDRAULIC PRESS | 2 |

| PNEUMATIC SPM | 2 |

| MANUAL SINGLE SPINDLE LATHE | 7 |

| THREAD ROLLING | 1 |

| DRILLINGS | 8 |

| CENTERLESS GRINDER | 1 |

| TAPPING SINGLE SPINDLE | 3 |

| GENERATOR | 1 |

.

| IN HOUSE SYSTEMS |

|---|

| FIRST OFF , LAST OFF, STAGE & PRE DESPATCH INSPECTION AS PER CONTROL PLAN |

| PFMEA |

| SPC STUDY |

| LAYOUT INSPECTION |

| MSA |

| MACHINE, FIXTURE & TOOL MAINTENANCE |

| INSTRUMENTS & GAUGES CALIBRATION |

| MONITORING KPI FOR ALL PROCESSES |

| OPERATOR TRAINING |

| MONITORING OF SAFETY SYSTEMS |

| RAW MATERIAL CONTROL |

| OUT SOURCED PROCESS CONTROL |

| CONTINUAL IMPROVEMENT IN ALL PROCESSES |

.

| ORGANIZATION STRENGTH |

|---|

| This supplier is used Improvement technique by SPC/ Kaizen/Poke Yoke/5’S/ PPM |

| Registered Customer complaints/Rejection in the Log Book & Analyze the root cause. |

| Best Storage & house keeping of Material/ Tooling/Receiver Gages/ Finished Goods/Dispatch. |

| Every Area is Defined with Traceable. |